Our Product

Products You Can Rely on. People You Can Trust.

EHT for PCP

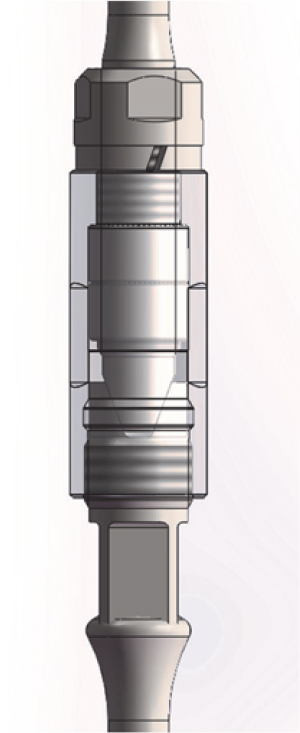

The Ultimate PCP Rod Solution – EHT®

Conventional approaches of inserting traditional sucker rods for PCP application often come short in meeting the higher torque and other unique requirements of PCP. In 2006, engineers at Exceed Oilfield Equipment started research and development on the first PCP specific rod to Increases Torque Capacity and Reduce Connection Failures that plague current PCP string designs. The current generation EHT® features our patented locking dove-tail connection and case hardened rod body. Overall, it offers 20-30% higher torque. Customers that switched to EHT® have seen benefits of higher torque capacity range, less failures at coupling and pin connections, and decrease in gearbox loading.

Special Connection

- Dove-tail interlocking design

- orque now distributed back into the sucker rod, not the coupling

- Couplings serve as non-torque bearing connection

EHTH®

- Case hardened body

- Dove-tail lock connection

- Anti-tripping coupling

Other Approaches

- Adapting existing rod

- Modify coupling thread

- Increased body size

7/8 EHT® replace 1″ DR

- Customers have been able to run 7/8″ EHT in place of a standard 1″ “Drive Rod”, while achieving higher torque and less total downhole weight.

7/8” EHT® offers higher maximum torque than competitor’s 1” PC Rod

When designing an artificial lift system with a Progressive Cavity Pump (PCP), the Maximum Torque offered by the sucker rod is the most import parameter to consider during rod selection. Exceed Oilfield Equipment’s EHT® rod dwarfs the competitions when compared the torque value. Comparing to competitor’s 1” PC rod, 1” EHT offers 35% higher torque. The 7/8” EHT® rod, despite having a 24% smaller body size, still delivers 10% higher maximum torque value compared to 1” drive rod from competition. This allows customers who are currently using 1” drive rod two alternative options, switch to 1” EHT® for significantly increased reliability or 7/8” EHT for much more efficient operation.

WHY? Torque ratings are generated by manufacturers at the rod body, not the pin and coupling connection. The pin and coupling connection is the weakest point of the rod string simply because it has the most variables. Each rig hand and rig crew will apply different torques, thus creating inconsistent connections that are susceptible to pin breaks and coupling failures. Exceed’s EHT ® connection removes these variables all together so the operators can be confident in reaching the optimum torque values.

Special Connection

- Dove-tail interlocking design

- orque now distributed back into the sucker rod, not the coupling

- Couplings serve as non-torque bearing connection

20-30% Higher Torque

| Rod Size | Maximum Torque (Nm) |

|---|---|

| 7/8″ 1800 | 1800 |

| 1″ | 2100 |

| 1-1/8″ | 4100 |

Contact Us

Our team is ready to assist you with top-notch solutions and services.

Send Us a Message

“An Exceed representative will contact you shortly”

24 Month Limited Warranty

Contact Information

Get in touch with Exceed Oilfield Equipment today for all your specialized energy industry needs.